Welcome to the world of industrial ice production, where efficiency, quality, and reliability are king. This article is dedicated to helping you understand the performance requirements of the direct cooling ice block machine, a critical asset in the ice-making industry.

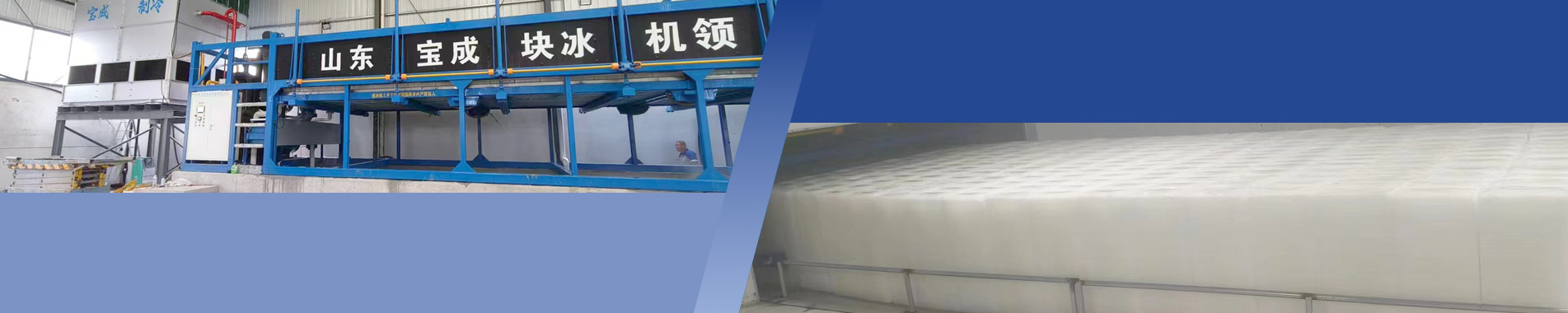

The direct cooling ice block maker, like the BAOCHARM 10 tons ice block machine exported to Malaysia, is designed to produce block ice of optimal quality. The water used for ice production adheres to GB5749 regulations, ensuring the safety and purity of the ice produced. The block ice should be dense, flawless, with a regular shape, and each block should not weigh less than 95% of the stipulated mass.

An essential performance requirement is the hollow ratio of the produced block ice. Although hollow blocks are permissible, the hollow ratio should not exceed 5%. This ratio is calculated by measuring the volume of unfrozen water in the center of the ice block against the total ice block volume.

The actual ice production of the block ice machine should not be less than 95% of the nominal ice production indicated by the manufacturer. Similarly, the actual power consumption should not exceed 110% of the nominal power consumption. These requirements ensure that the machine operates at optimal energy efficiency, contributing to cost-effective operations.

The block ice machine should operate smoothly with no continuous dripping at the ice outlet. No part of the cooling system should leak refrigerant, and there should be no water leakage in any part where the water for ice making circulates. The outer surface of the ice mold insulation layer, the refrigeration equipment, and the pipe surface with insulation material should not exhibit bead-level or streaming condensation.

Lastly, the paint peeling off should not exceed 15%, ensuring the machine's longevity and aesthetic appeal. This requirement not only preserves the machine's appearance but also protects the underlying material from potential damage.

Community charging overall solution covers all application

Professional Team

Professional Team

Quality Assurance

Quality Assurance

Understanding the performance requirements of the industrial block ice maker machine is crucial for anyone in the ice-making industry. Ensuring that your machine meets these standards guarantees high-quality ice production, efficient energy usage, and long-lasting machine operation.

Ready to revolutionize your ice-making process with a direct cooling ice block machine? Visit BAOCHARM Industrial Ice Machine Factory for the best solutions tailored to your needs. Remember, the right machine is an investment in quality, efficiency, and sustainability. Contact us today for more in ice production solutions.

Our Contacts

Email: sales@baocharm.com

WhatsApp: +86 17663537579

Wechat: +86 17663537579

Working Hours: Mon ~ Sat 8:30 AM - 5:30 PM