Gratitude is due to our engineers for capturing the essence of the installation site, as their videos provide us with a unique opportunity to delve deeper into the subtle distinctions between our domestic and export ice-making equipment.

It is against this practical backdrop that we are able to explore and explain the nuanced differences that define our block ice machines, whether they are tailored for the familiar terrain of our local market or the varied climates and conditions they will encounter across the globe.

In the realm of industrial ice-making equipment, the nuanced differences between domestic and export machines are often overlooked yet critically important. As a company with a strong legacy in the manufacturing of high-caliber block ice machines, we take pride in our ability to tailor our equipment to the specific demands of diverse markets. This blog post aims to delve into the structural distinctions of our block ice machines designed for the domestic market versus those crafted for international export, showcasing our commitment to professional excellence and precision in equipment manufacturing.

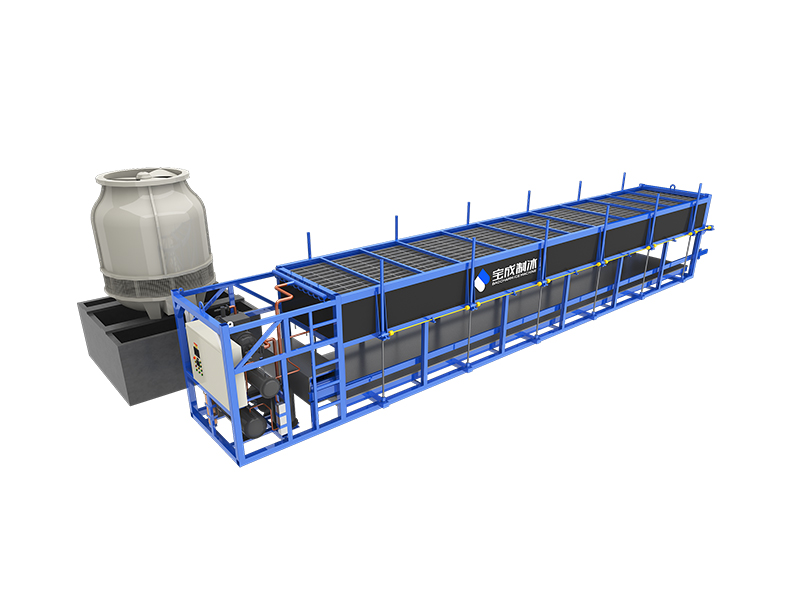

Our domestic block ice machines are designed with a level of flexibility that reflects the variety of transportation options available within the country. This adaptability allows us to engineer solutions that are intricately aligned with the actual needs and spatial constraints of the installation site.

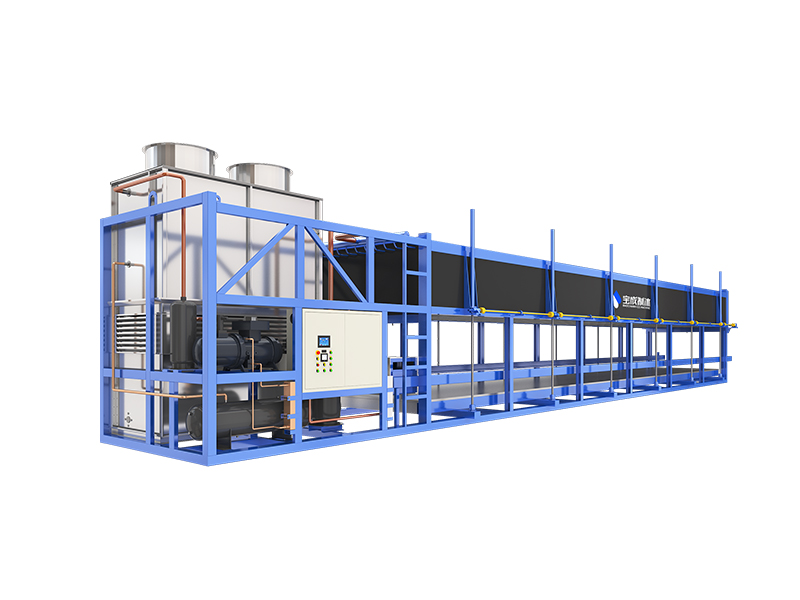

Conversely, when it comes to exporting our equipment, we must navigate the constraints imposed by container shipping dimensions. Currently, our export-ready machines are designed to a largest capacity of 20 tons per unit to optimize shipping logistics. While we are capable of producing machines with greater production capacities, such customizations necessitate special transportation arrangements, which may incur additional costs.

For our export models, we prioritize ease of installation, particularly in the design of the cooling system. We opt for water cooled systems that utilize cooling tower units to cool the compressor units. This choice offers several advantages:

The design of our compressor units for export machines is meticulously planned to accommodate local voltage standards, compatibility with generators, and the unique challenges posed by extreme temperatures, such as those areas found highest temperature reach to +50℃. Rest assured, our robust technical expertise and extensive experience enable us to meet and exceed expectations in any scenario.

We offer a wide selection of ice machine refrigerants, including R22, R507, and R404a. However, due to hazardous goods shipping restrictions for sea transport, our machines are shipped without refrigerant, allowing for local filling by the client upon arrival.

Our operational systems are a testament to our innovative spirit. We employ a proprietary operating system that exudes a high-tech aura, with dual-language capabilities and the option for custom multi-language interfaces. This ensures that users can monitor equipment status and operate the machine with greater clarity and ease.

Before any machine is deemed ready for export, it undergoes a rigorous quality control process. This includes two to three pre-shipment trial runs to guarantee that every component functions flawlessly. Only when we are fully confident in the machine’s performance do we proceed with shipping arrangements.

In conclusion, our approach to manufacturing block ice machines for domestic and export markets is underpinned by a dedication to excellence and a deep understanding of the nuanced requirements of each. By maintaining the highest standards of professionalism and precision, we aim to enhance customer trust and solidify our position as a leading provider of ice-making solutions worldwide.

Our Contacts

Email: sales@baocharm.com

WhatsApp: +852 5510 1036

Wechat: +86 17663537579

Working Hours: Mon ~ Sat 8:30 AM - 5:30 PM